Architecture using Precast and Prestressed Construction

In a quiet and nature-rich environment in Nagano Prefecture, Japan, where streams weave through a thick forest of red pine, Nendo created tunnel-like architecture for a furniture facility through a combination of precast and prestressed construction methods in a display of superlative design tenacity.

Nendo uses the most intense prestressed method, used in in heavy engineering structures such as bridges, in which the parts are aligned and then tightened with wires to connect them, to arrive at the architecture of a furniture storage facility. The result of using precast and prestressed method is a seamless and smooth surface finish, obtaining a tight seal, a durable building and contemporary architecture.

Nendo uses the most intense prestressed method, used in in heavy engineering structures such as bridges, in which the parts are aligned and then tightened with wires to connect them, to arrive at the architecture of a furniture storage facility. The result of using precast and prestressed method is a seamless and smooth surface finish, obtaining a tight seal, a durable building and contemporary architecture.

The building is composed of four stacked “tunnels” covered with a roof in the centre. In addition to a long, narrow storage room with a depth of approximately 40 meters, there are two smaller storage rooms, but it is envisioned that more will be added to the site in the future as the collection grows, the design team at Nendo clarifies. The kitchen, bathroom, toilet, and other water facilities are concentrated on the first floor, and a compact bedroom and a study are located on the second floor.

The building is composed of four stacked “tunnels” covered with a roof in the centre. In addition to a long, narrow storage room with a depth of approximately 40 meters, there are two smaller storage rooms, but it is envisioned that more will be added to the site in the future as the collection grows, the design team at Nendo clarifies. The kitchen, bathroom, toilet, and other water facilities are concentrated on the first floor, and a compact bedroom and a study are located on the second floor.

For precast construction, common parts are moulded in a factory and assembled on site. An example of its applications in infrastructure projects is the box culvert (box-shaped concrete structures), used to store waterways, pathways, power lines, and communication lines buried underground. However, since the method itself does not provide a leak-free composition nor does it allow for stacking, both necessary for this design, prestressing was also used to connect the parts together.

For precast construction, common parts are moulded in a factory and assembled on site. An example of its applications in infrastructure projects is the box culvert (box-shaped concrete structures), used to store waterways, pathways, power lines, and communication lines buried underground. However, since the method itself does not provide a leak-free composition nor does it allow for stacking, both necessary for this design, prestressing was also used to connect the parts together.

“The common square-shaped parts weigh approximately 12 tons each, and a total of 63 of these parts were used. The size of the parts was derived from the loading size of the delivery truck and the weight that could be lifted by a crane. The 45-degree reinforcement at the entry corner, which is also found in general box culverts, serves as a brace and enhances earthquake resistance. By connecting these parts, a slender, tunnel-shaped space with an internal dimension of approximately 2 x 2.3 m was created. Fourteen wires were used to connect each “tunnel” and care was taken to apply uniform tension to each wire at all times. The work involved gradually tightening the wires over time until a tension of 46 tons was finally applied to each,” says the design brief.

The windows were made without metal frames as much as possible, and high-transparency glass measuring up to 10 meters in length was fixed into the grooves in the same manner as shoji screens.

The gravel and plantings used in the exterior were also arranged in the interior to draw the outside environment into the interior. To make it easier to walk on, the gravel was partially hardened with resin. Instead of just pouring resin over the gravel, which is usually the case, the resin was applied to the base first and then gravel was laid on it so that the surface wouldn’t become glossy.

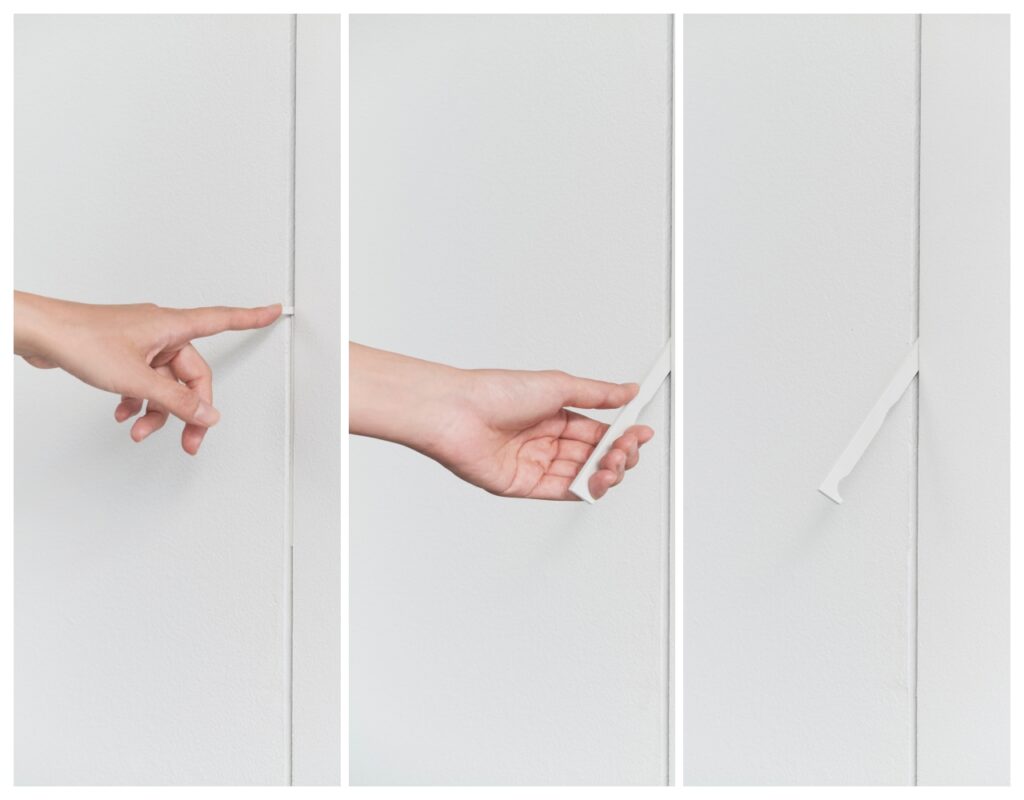

In addition, the door handles would have looked abrupt if installed as-is, so an original handle was designed, which hides in the small gap between the door and the wall. The bathtub is carved into the floor, such that the water surface aligns with the floor, creating the appearance that the tunnel shape is continuous.

In addition, the door handles would have looked abrupt if installed as-is, so an original handle was designed, which hides in the small gap between the door and the wall. The bathtub is carved into the floor, such that the water surface aligns with the floor, creating the appearance that the tunnel shape is continuous.

Each component of the design treated as a product that is designed in a way that is optimum for its use as well as the overall design aesthetics of the building.

Each component of the design treated as a product that is designed in a way that is optimum for its use as well as the overall design aesthetics of the building.

The resulting space is less architectural, but rather a project that combines civil engineering concepts with product design, says the team at Nendo.

The resulting space is less architectural, but rather a project that combines civil engineering concepts with product design, says the team at Nendo.