The Cheer Project Recycles Pine Needles

The Cheer Project develops the abundantly available pine needles into a recyclable material and for this innovation, Gaurav M K Walli, the designer behind the material and the products made out of it, won second place at the RO Plastic Prize 2021 in the category ‘Responsible Innovation.’

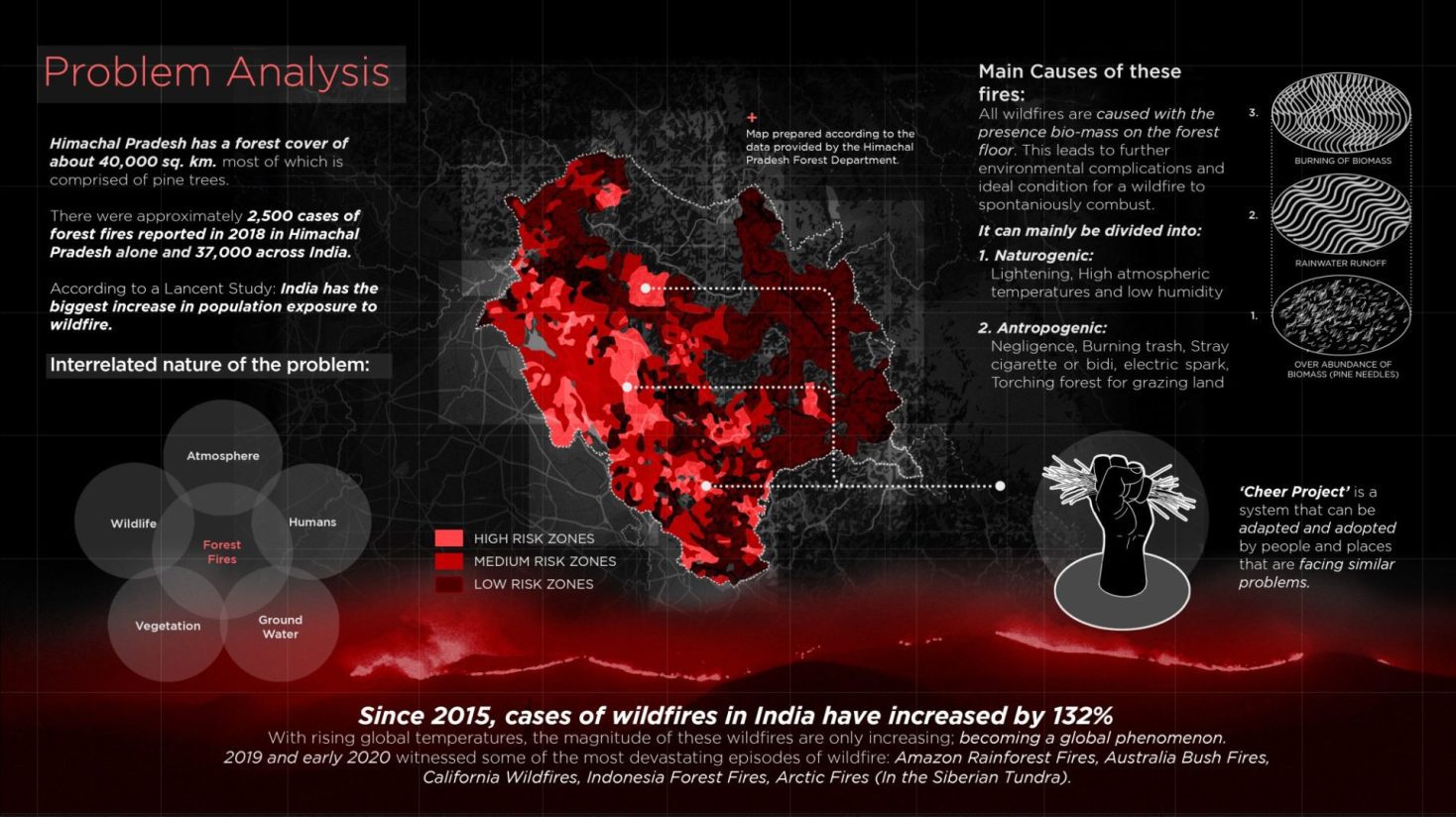

Designer Gaurav M K Walli lives at the foothills of the Himalayas in Himachal Pradesh and has witnessed forest fires every year during his four years of college. “Having lived at the foothills of the Himalayas, the pine forests became a part of my daily life. It is a tragic sight to see the beautiful flora get engulfed in flames every summer. With a forest cover of about 40,000 square kilometres, the environmental distress caused by these fires is incalculable with no significant solution to the problem,” says Gaurav of the hazard he lived with, that triggered the need for a design intervention.

Designer Gaurav M K Walli lives at the foothills of the Himalayas in Himachal Pradesh and has witnessed forest fires every year during his four years of college. “Having lived at the foothills of the Himalayas, the pine forests became a part of my daily life. It is a tragic sight to see the beautiful flora get engulfed in flames every summer. With a forest cover of about 40,000 square kilometres, the environmental distress caused by these fires is incalculable with no significant solution to the problem,” says Gaurav of the hazard he lived with, that triggered the need for a design intervention.

With around 2800 forest fires recorded in 2018, the problem was getting severe and the need for intervention was the need of the hour.

“In search of a solution, I drew inspiration from biomaterials. My plan of action was to convert pine needles into a bio-based, recyclable, and biodegradable bio-composite material. Produced through a system of a process that gives pine needles, some functional use, the entire process empowered local communities and provided them with economic sustenance, while providing an alternative to plastic,” he says as he started adopting the movement of biomaterials at a rural level contributing to the global fight for sustainability. Thus, was born the ‘Cheer Project’, research on pine needles in which this abundant, overlooked and unwanted material is developed into a 100% bio-based, recyclable and compostable bio-composite material.

“In search of a solution, I drew inspiration from biomaterials. My plan of action was to convert pine needles into a bio-based, recyclable, and biodegradable bio-composite material. Produced through a system of a process that gives pine needles, some functional use, the entire process empowered local communities and provided them with economic sustenance, while providing an alternative to plastic,” he says as he started adopting the movement of biomaterials at a rural level contributing to the global fight for sustainability. Thus, was born the ‘Cheer Project’, research on pine needles in which this abundant, overlooked and unwanted material is developed into a 100% bio-based, recyclable and compostable bio-composite material.

The name “Cheer Project” comes from the colloquial name of the pine, which when read in English becomes “cheer” or a “shout for joy or in praise”. “That is exactly what the humble pine will one day do for its native communities: bring them joy,” adds Gaurav.

Expanding on the technical aspects of the material, Gaurav says, “The binder for the material is derived from a natural binder used by the local communities of Himachal Pradesh called ‘Layie’. I later tweaked the composition of the binder to make it according to my needs. The strength and flexibility of the material can be determined by the amount of each of the components in the binder. But the strength test of the material in is yet to be conducted.”

Expanding on the technical aspects of the material, Gaurav says, “The binder for the material is derived from a natural binder used by the local communities of Himachal Pradesh called ‘Layie’. I later tweaked the composition of the binder to make it according to my needs. The strength and flexibility of the material can be determined by the amount of each of the components in the binder. But the strength test of the material in is yet to be conducted.”

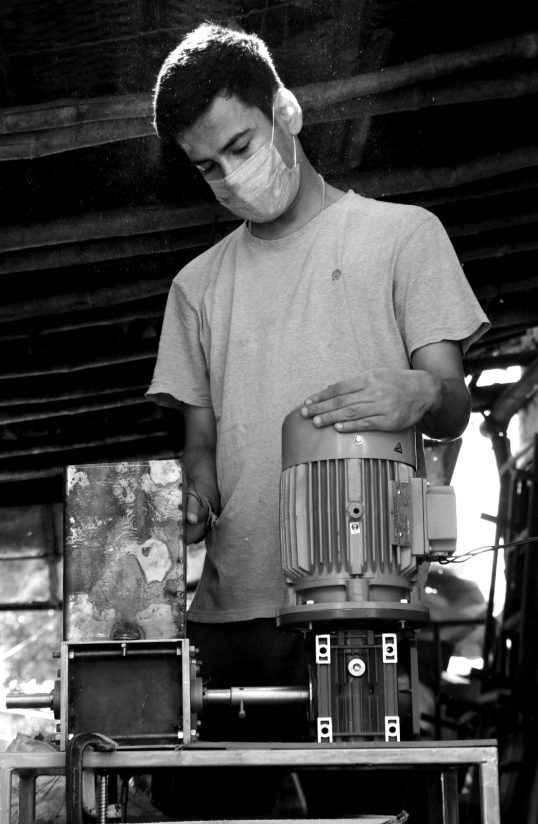

Cheer Project offers a sustainable and socially viable solution to the environmental hazards caused by an overabundance of dried pine needles on the forest floor. Through a holistic approach, Cheer Project’s production process unveils the dormant potential of pine needles while also empowering indigenous communities by creating livelihood opportunities for them. The proposed modus operandi is circular: raw material is procured by indigenous communities from nearby pine forests, the collected needles are then processed into a fibre with locally-built, low-cost machinery, this pine fibre is further mixed with natural binders to make the pine composite.

“The developed composition is 100% bio-based, compostable, recyclable, fire retardant, water repellent and causes no pollution or waste in the process. This bio-composite material can be used by local artisans to manufacture sustainable products and revenue generated through the sale will further strengthen the rural economy while restoring the pride of the locals in their work,” says Gaurav.

“The developed composition is 100% bio-based, compostable, recyclable, fire retardant, water repellent and causes no pollution or waste in the process. This bio-composite material can be used by local artisans to manufacture sustainable products and revenue generated through the sale will further strengthen the rural economy while restoring the pride of the locals in their work,” says Gaurav.

“The fight against plastic pollution is juxtaposed against the endeavour to sustainably support stakeholder communities. Cheer Project seeks to democratise the process of problem-solving through design. The ultimate concept rests on the fusion of local craftsmanship and sustainable utilisation of a naturally abundant novel material; the rediscovery of the humble pine needle.”

All Images Courtesy Gaurav Walli.